At ONYX Specialty Processing, we’re thrilled to announce the upcoming activation of our new passivation system, scheduled to go live on September 1st, 2024. This significant enhancement to our processing capabilities marks a pivotal development in ensuring the longevity and durability of the metal components we manage.

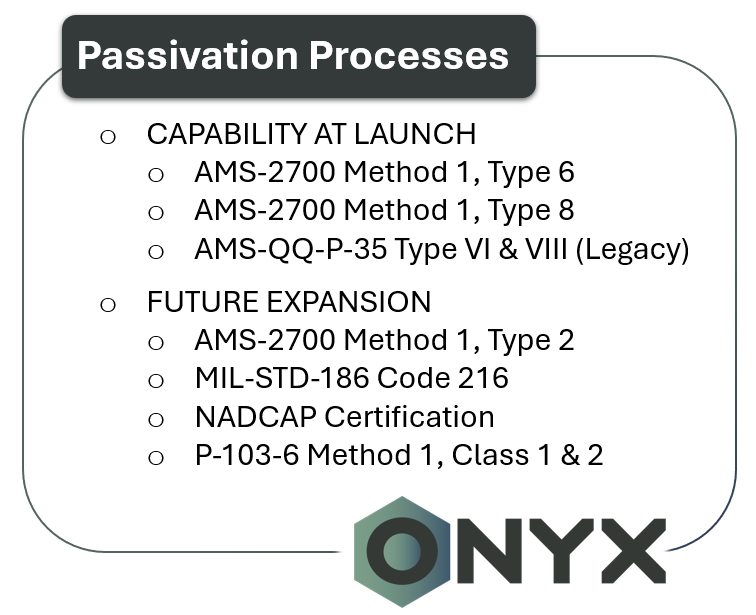

Passivation, a chemical treatment, is essential for protecting metals from corrosion. It works by meticulously removing free iron particles and other contaminants from the metal surface, creating a thin yet robust protective oxide layer. This barrier significantly boosts the metal’s resistance to corrosion and extends its lifespan, making it an indispensable process for maintaining the structural integrity of aerospace components. Our initial certification efforts are focused on achieving AMS-2700 Method 1, Type 6, and Type 8 approvals, setting the stage for future expansions.

In alignment with our commitment to innovation and quality, our team has dedicated considerable resources to seamlessly integrate this system into our existing operations. The introduction of automated passivation processes ensures both efficiency and consistency, guaranteeing high-quality outcomes with every batch processed.

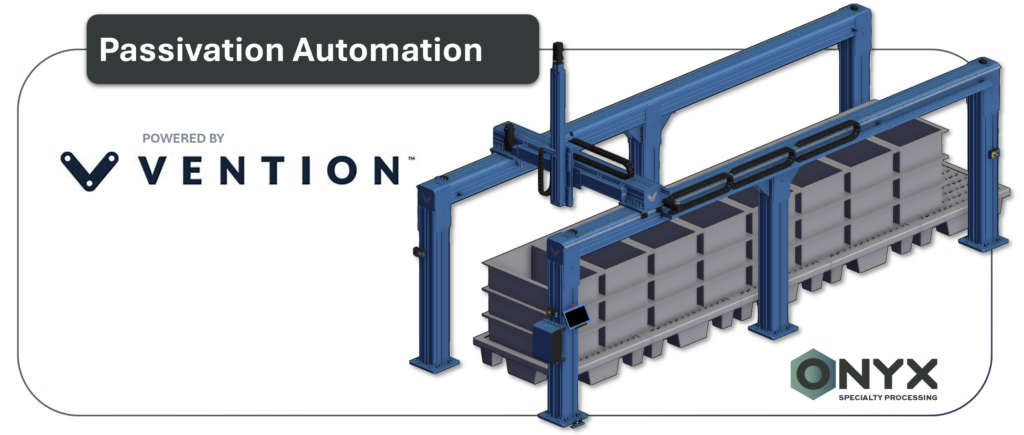

To further our commitment to technological advancement and operational efficiency, we are also excited to announce plans to fully automate our passivation system with a custom-designed setup supplied by Vention. Known for its innovative approach to modular industrial automation, Vention will help us enhance production efficiency through scalable, user-friendly automation solutions. The automated system is expected to be operational by the end of the year, which will streamline our processes, significantly reducing both costs and processing times for our clients.

We are determined to have the passivation system fully operational by September 1st and are on schedule to achieve this goal. This new capability will significantly bolster our capacity to deliver top-tier aerospace components, meeting the most stringent standards for durability and performance.

Keep an eye on our updates as we near the launch date. We are eager to demonstrate the capabilities of our fully operational passivation system and its impact on the quality of our services.

Leave a Reply

You must be logged in to post a comment.